The classic WIESE continuous bucket conveyor has the robust conveyor belt as its central element: rubber chains and buckets are connected, ensuring the reliable transport of your bulk materials.

WIESE continuous bucket conveyors

Structure

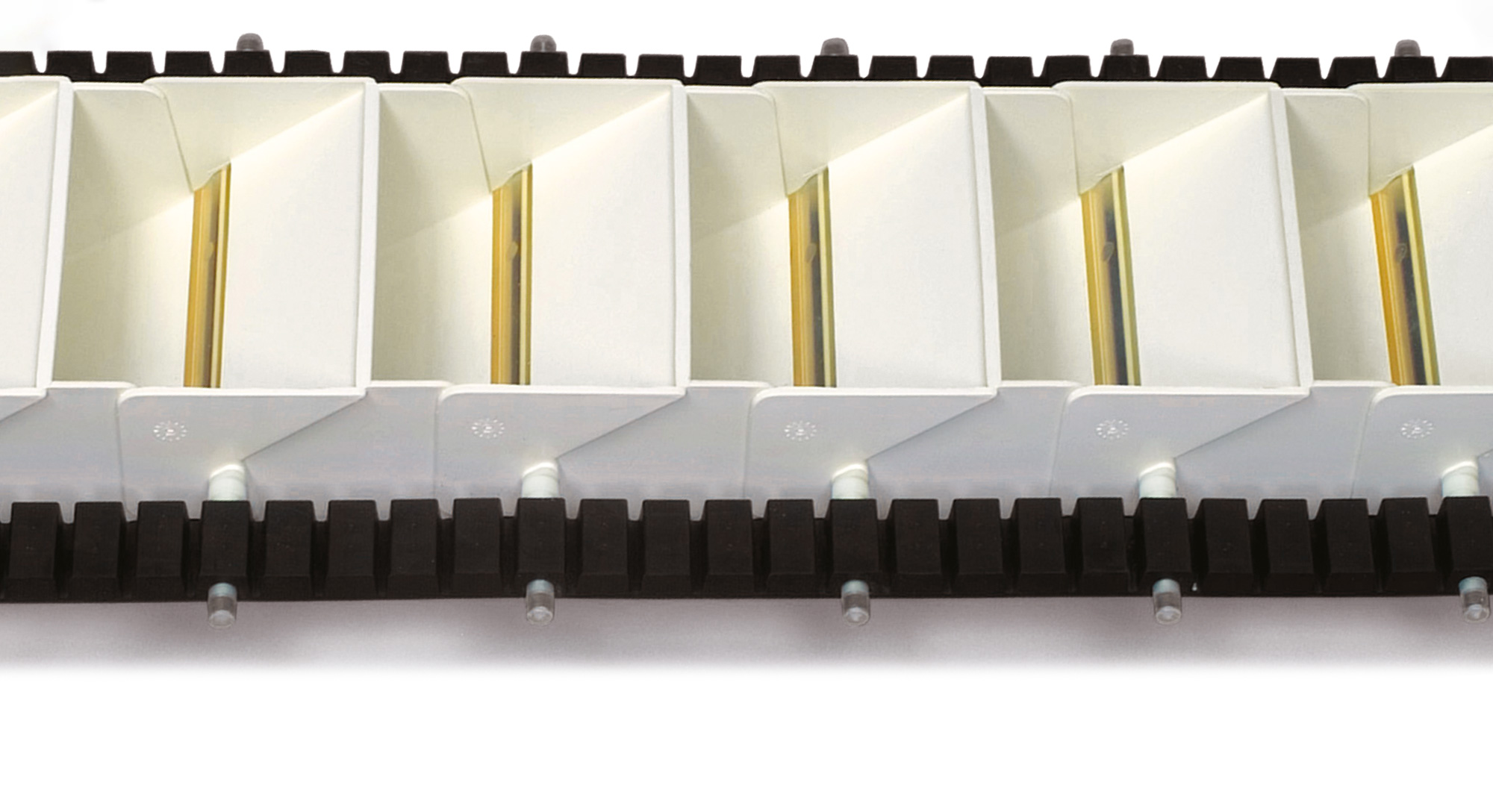

All WIESE continuous bucket conveyors have the same basic structure. Buckets designed especially for the transport of bulk materials of all kinds are mounted between two WIESE rubber chains.

The WIESE continuous bucket conveyors of type SEB are characterised by a fully enclosed, seamless conveyor belt. This means that two neighbouring buckets are connected to each other by a flexible rubber flap, known as the connecting flap. This connection is a positive-locking one and gap free, guaranteeing that the bulk materials cannot trickle down between the buckets.

Product loss is minimal. Despite this, the design is flexible enough to allow materials to be transported both horizontally and vertically without any product handover points. The length of the transportation route is virtually unlimited. Various materials are available for every component of the bucket conveyor. The materials are chosen based on the requirements relating to compatibility, temperature and the physical and chemical properties of the materials being transported.

Individual parts, such as buckets or connecting flaps, can be individually replaced, contributing to the high degree of system availability.

Function

The standard conveying speed of 0.5 m/s is the ideal compromise between capacity and product-sparing and loss-free transportation. However speeds of up to 1 m/s can also be accommodated without problems. All of the components involved are coordinated with each other to ensure high availability and reliability.

WIESE continuous bucket conveyors are designed to deliver maximum operational dependability.

The self-contained, if necessary dust-tight and even gas-tight housing construction ensures that products and dust remain inside the housing and do not escape into the environment around them. So even if bulk materials that are hazardous to health are being conveyed, there is no risk of nearby work areas being contaminated. All bucket conveyors can also be equipped with connections for extractor systems.

A controlled product feed is essential for the use of our bucket conveyors. When coupled with optimised product feed, the result is a virtually loss-free conveyor system.

At the bucket conveyor handover point, the conveyed material falls out of the bucket due to the influence of gravity and is not ejected, as with standard elevators. This is significantly more gentle on the product and keeps dust development within manageable limits.

All parts that come into contact with the product can also be supplied in food-safe quality. This of course includes up-to-date certificates in accordance with applicable standards such as EC 1935/2004 and 10/2011 or 21 CFR 175-181.

The low-maintenance SEB continuous bucket conveyor is especially suitable for customers who set particular store by cost-effectiveness and productivity and who want to keep their maintenance and repair costs as low as possible.

All continuous bucket conveyors are also available with an ATEX certificate for dust explosion zones 20 to 22.

Transportation lengths of up to 50 m vertically or 100 m horizontally have already been created using Wiese continuous bucket conveyors. Conveyor capacities of up to 100 m³/h can also be achieved.

Among their other qualities, WEISE continuous bucket conveyors are ideal for transporting anything from fine dusts of micrometre size through to coarse products.

There is a solution we have customised for every application.